Use coding to enhance and protect your brand

Package design helps differentiate your product and communicate the quality of your brand. In addition to imparting important information on the packaging, product codes can help enhance the quality image of your products. Further, value-added coding strategies can help minimize pre-printed inventory or protect your brand with anti-counterfeiting or diversion solutions. Videojet has coding solutions to help you get your ideal code on every product, time after time, while delivering the flexibility and efficiency that you need.

- Applications

- Line Integrations

- Documents

- Overview

- RigidPlasticContainers

- FlexiblePlasticandPaper

- GlassBottlesandJars

- SpecialtyContainers

- MetalAerosolCans

- FoldingCartons

- Case

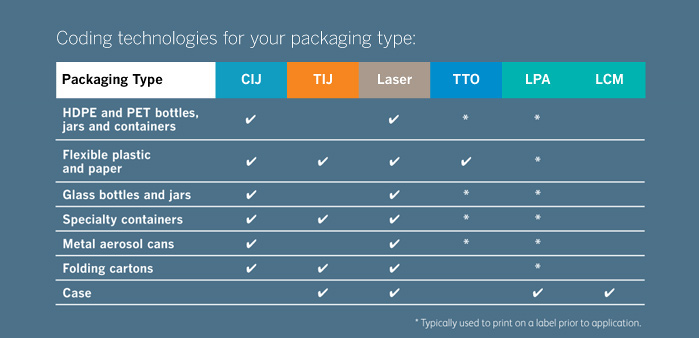

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Thermal Transfer Overprinting (TTO)

A digitally controlled printhead precisely melts ink from a ribbon directly onto flexible films to provide high resolution, real-time prints.

Ink-based, non-contact printing using heat and surface tension to move ink onto a package surface. Generally used to print 2D DataMatrix and other bar codes.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Label Printer Applicator (LPA)

Prints and places labels of various sizes on multiple package types.

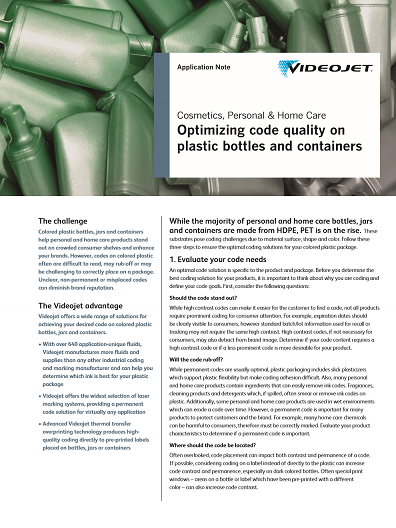

Over 80% of personal and home care bottles, jars and containers are made from either HDPE or PET1.

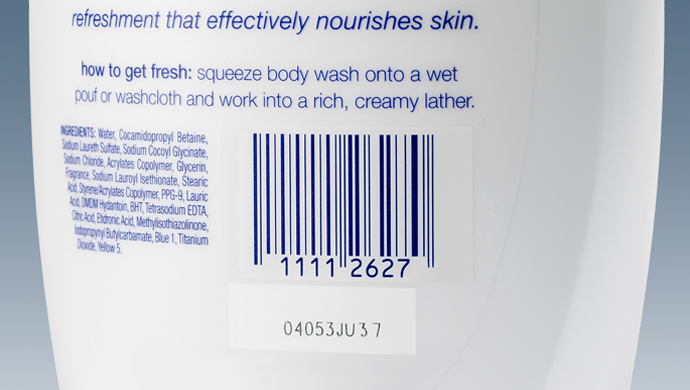

Plastic packaging includes slick plasticizers which support plastic flexibility but can make coding difficult. Therefore, consider code contrast and resilience requirements and make sure you obtain product samples before you determine the optimal coding technology for your package.

Our expert sales and service teams will help you chose the right coding technology and keep it running effectively on your line.

Continuous Ink Jet

(CIJ)

- high-speed, non-contact printing, even on irregular shapes

- wide range of both dark and light colored inks for maximum contrast

- ideal for both direct-to-plastic and label printing

- mobile printhead enables code placement almost anywhere on package, including closures and curved bottoms, for maximum flexibility

Laser Marking Systems

- creates clear and permanent codes that are ideal for detergents, cleaners and products used in wet environments

- no inks or fluids required, reducing your environmental footprint

- ideal for both direct-to-plastic and label printing especially in pre-printed knock-out boxes

1 Euromonitor packaging database. Based on 2012 package type estimates.

Many coding technologies are effective on flexible plastic and paper packaging. While films, pouches, sleeves and bags can all be cost-effective packaging options, managing the numerous pre-printed films for every fragrance, color and product can be challenging and costly.

Videojet has a wide range of coding technologies to give you the capability to print product information, bar codes, ingredients, logos and other information during packaging by batch, line and even individual unit. This can reduce your hassle and costs while increasing your manufacturing flexibility.

Thermal Transfer Overprinting (TTO)

- ideal for coding on plastic film prior to filling

- sharp bar codes and logos for clear customer communication

- perfect for adding color numbers, logos, names or bar codes on plastic sleeves

Thermal Ink Jet (TIJ)

- easy to use and maintain due to the innovative no-mess ink cartridge system

- prints clear bar codes, logos and other data

- ideal for paper-based applications, such as the cardboard back of retail blister packages

Laser Marking Systems

- a chemical reaction on certain types of film results in a color change which gives you sharp, clear codes

- limited supplies required

- ideal for paper and some plastics

Continuous Ink Jet (CIJ)

- specialized inks for optimized adhesion and code durability

- seamless integration into flow-wrappers, vertical form, fill and seal and other machinery

- codes on most flexible paper and plastic package types

Defending the reputation of your business and your products is not easy. Product diversion to unauthorized channels and counterfeiting can reduce profits, tarnish brand image and create safety risks for your customers.

Our advanced coding technologies and supporting software solutions, however, can give you the supply chain control you need to help prevent these threats. These solutions can be as simple as using a laser marking system to ensure a permanent code on your package to an integrated software solution that incorporates anti-counterfeiting elements into your codes.

Continuous Ink Jet (CIJ)

- print sizes available with compact 50 micron nozzles for your small, hard-to-code areas

- high contrast text ideal for customizing bottles with color numbers or names

- versatile design is easily modified for different package sizes and shapes

- UV inks enable covert coding solutions

Laser Marking Systems

- clear codes, logos and text etched into glass packaging ensures permanence and brand protection

- removal of top layer of paint on decorated bottles gives high contrast

- possible to code inside of package to prevent tampering

Thermal Transfer Overprinting (TTO)

- prints on labels prior to placement on glass

- ribbon saving technology minimizes supply usage

- in-line print quality often on par with pre-printed content

Due to their shape, use and dispensing method, many personal and home care products such as cosmetics, skin and lip care, deodorants and even air fresheners come in a variety of specialized containers. In fact, your package design often differentiates your product and can be integral to your success.

Make sure your coding doesn’t detract from your great package styling by considering coding during the design process, then choose the optimal coding technology for your specialized package.

Videojet’s wide range of printing technologies can help ensure your coding is an integral part of your winning packaging design.

label and

package

Laser Marking Systems

- mobile 3020 Laser Marking System is easily adjusted for varying package sizes

- scribing technology and large marking fields provide excellent code quality

label

Label Printer Applicator (LPA)

- modular, robust design, which helps ensure maximum versatility

- capable of high loads, with extremely accurate control or exceptional speeds

- can be easily integrated into existing line systems

label

Thermal Transfer Overprinting (TTO)

- ideal for dark packaging when a contrasting code is required

- prints on label prior to application

- many different ribbon colors available

label and

package

Continuous Ink Jet (CIJ)

- versatile coding solutions for almost any package material, size or color

- easy-to-use with interactive touchscreen

- Smart Cartridge™ fluid system virtually eliminates waste, mess and mistakes

Metal aerosol cans are used around the world to dispense a variety of cosmetics, personal and home care products from polishes and cleaners, insecticides and air fresheners to deodorants, hair spray and shaving cream.

However, coding on aerosol cans can often be a challenge due to the metal finishes and curved designs. Videojet offers coding solutions and service support for these and other difficult coding applications and can help keep your line running efficiently.

Continuous Ink Jet (CIJ)

- capable of printing on bottom of can, even with high curves

- patented CleanFlow™ technology combines a specially designed printhead and an auto cleaning function to reduce build-up and keep the printhead clean

- modular design delivers up to 12,000 hours of production between scheduled maintenance

Laser Marking Systems

- wide range of laser lenses, powers and technology types make sure that you can print on most kinds of metals and curvatures

- ideal for either engraving into the metal directly or the removal of a painted or labelled surface

Videojet coding solutions can do more than just add a batch, lot or date code to your package: they can simplify your operations and help reduce your manufacturing costs.

More coding in-line and onsite means you can customize packaging at the product or batch level resulting in quicker changeovers and more flexible manufacturing. With Videojet’s digital coding technologies, you can add color names or numbers, ingredients, bar codes or icons to your product in-line and to the outside of cartons.

Laser Marking Systems

- simple and clean method of marking text, bar codes or images while utilizing virtually no consumables

- a CO2 laser will remove the top layer of a pre-printed ink to expose the layer underneath, resulting in high quality and bright contrast

Continuous Ink Jet (CIJ)

- codes adhere to virtually all common carton materials including those with aqueous overcoats and varnishes

- reliable and cost effective coding method

- colored and pigmented inks available for dark boxes to create high contrast

- UV inks enable covert coding solutions

- invisible UV and IR inks can hide code in package design

Thermal Ink Jet (TIJ)

- high quality, high resolution print even after long printing breaks

- easy to integrate into packaging line for printing above or laterally

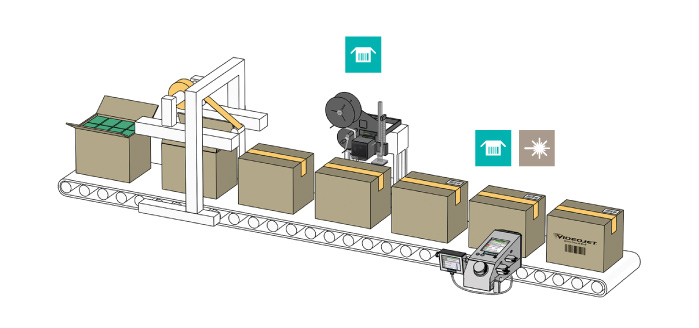

Achieving legible and accurate information on your cases is vital for effective supply chain management. Videojet has multiple ways to help you create supply chain traceable coding, that range from high resolution printing direct to the box to automatic label application.

Large Character Marking (LCM)

- high resolution printing of bar codes, logos and information marking

- cost-effective and dependable solutions

- eliminates the inconvenience and additional costs that can occur with labels and specialized pre-printed cases

- lower resolution valve jet option ideal for large text

Label Print & Apply (LPA)

- high quality thermal transfer coding direct to labels

- automatic applicator offers greater speed, accuracy and error prevention than hand labeling

Laser Marking Systems

- dark back, high resolution coding on Datalase® coded boxes without ink

- can print over large print area with a wide range of lenses

- fast printing speeds

Thermal Ink Jet (TIJ)

- designed to support the GS1 DataMatrix standards

- delivers optimal time management with combination of long decap and short drying time

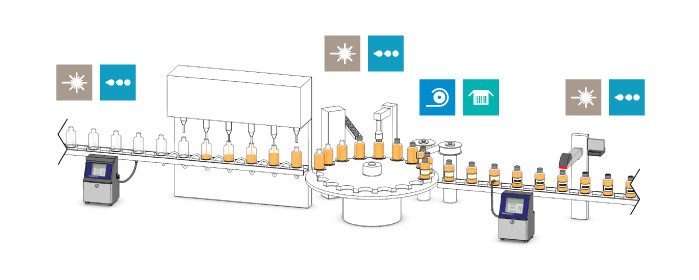

- Filler, Capper

- Cartoner

- Case Packer

Easy integration before, into or after your filler is key to your coding and marking success. Videojet printers can be integrated to multiple places on your line to maximize your flexibility and code quality.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Thermal Transfer Overprinting (TTO)

A digitally controlled printhead precisely melts ink from a ribbon directly onto flexible films to provide high resolution, real-time prints.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Label Printer Applicator (LPA)

Print and places labels of various sizes on multiple package types.

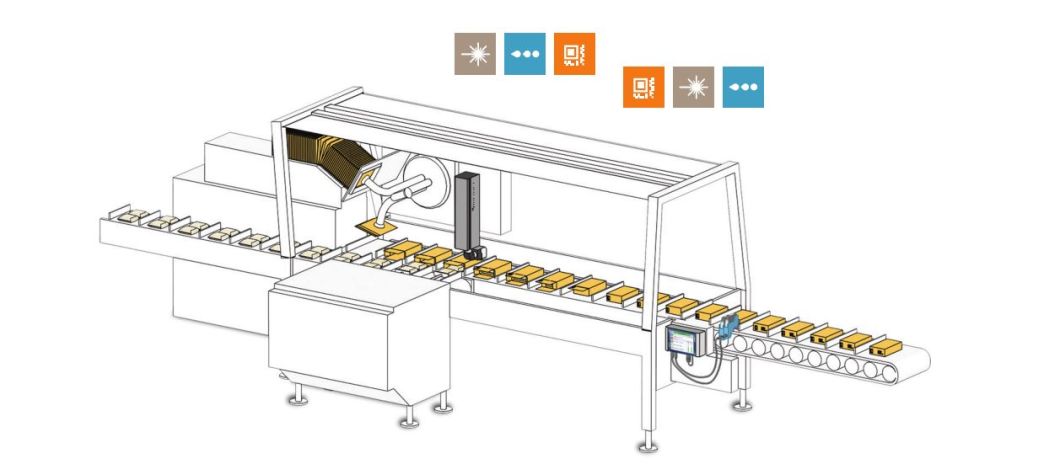

A range of technologies can be integrated with cartoning machines before or after packaging. Your optimal installation location will depend upon the size constraints of both your cartoner and your preferred coding technology.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

Fluid based, non-contact printing of up to five lines of text, linear and 2D bar codes, or graphics, printed on a variety of packaging types including stationary packaging via traversing systems.

Ink-based, non-contact printing using heat and surface tension to move link onto a package surface. Generally used to print 2D DataMatrix and other bar codes.

Printers are best integrated on your conveyor after the sealed case has been discharged. The type and amount of information you want to print on your case determines which solution is best suited to your operations.

Ink-based, non-contact printing of multiple data types (alphanumeric, logos and bar codes) in large sizes primarily used for secondary packaging such as cases.

Label Printer Applicator (LPA)

Print and places labels of various sizes on multiple package types.

A beam of infrared light focused and steered with a series of carefully controlled small mirrors to create marks where the heat of the beam interacts with the packaging surface.

- Brochures

- Application Notes

- Case Studies